Foundation Robotics

4 minutes read •

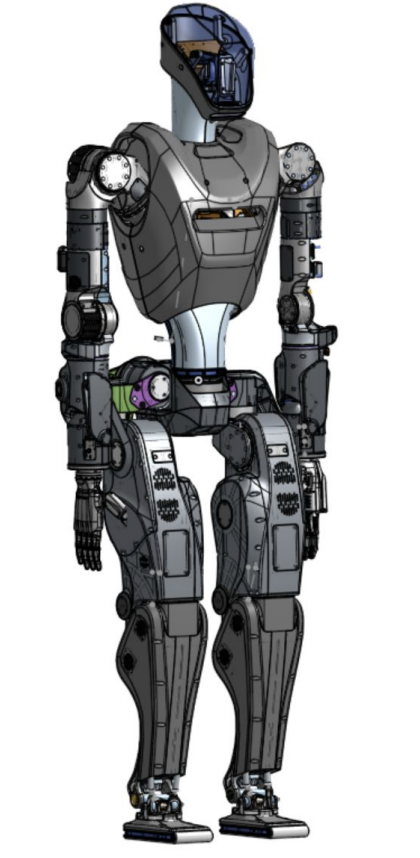

This past summer (2025), I had the opportunity to intern at Foundation, a rapidly growing humanoid robotics startup in San Francisco. The company was in the midst of scaling production for its first 100 MK1 humanoid robots, moving from prototype builds into repeatable, manufacturable systems. During this time, I helped develop and refine the assembly workflow by designing and fabricating manufacturing fixtures, authoring clear build instructions, and taking part in the hands-on assembly, debugging, and bring-up of full Phantom 1 humanoids. I also helped train and onboard new technicians, supporting the expansion of the manufacturing team to meet the company’s accelerated production timeline.

Below are a few internship highlights:

Humanoid Assembly & Debugging

- Independently completed the assembly of entire Phantom MK1 Humanoids including structures, linkages, motor encoder soldering, power and signal harnesses fabrication, actuator calibration

- Complete initial robot bring-up via simulation that involved URDF visualization and actuator signals

- Worked on manufacturing floor to complete humanoid repairs and often independent debugging

Manufacturing Design Projects

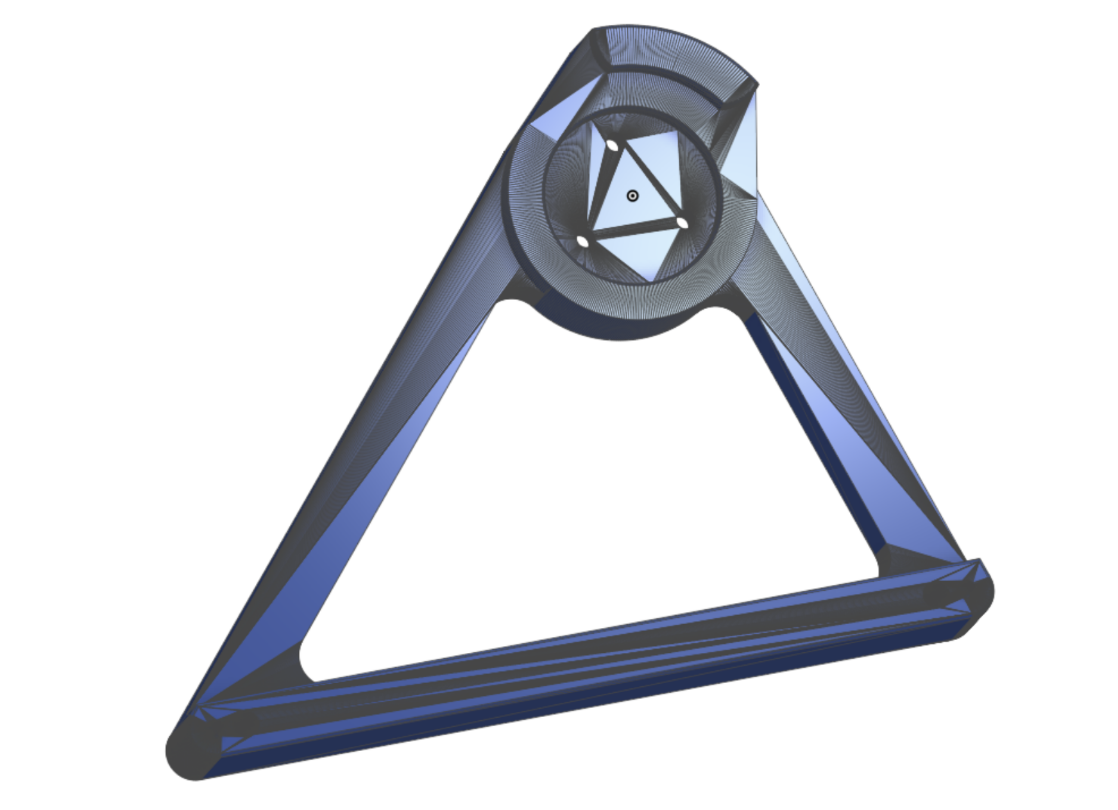

- Designed various manufacturing and work holding fixtures in OnShape for CNC milling. Examples include a jig to clamp down actuator encoder magnet rings to be milled down as well as an ankle zeroing fixture to establish neutral ankle position during bring-up

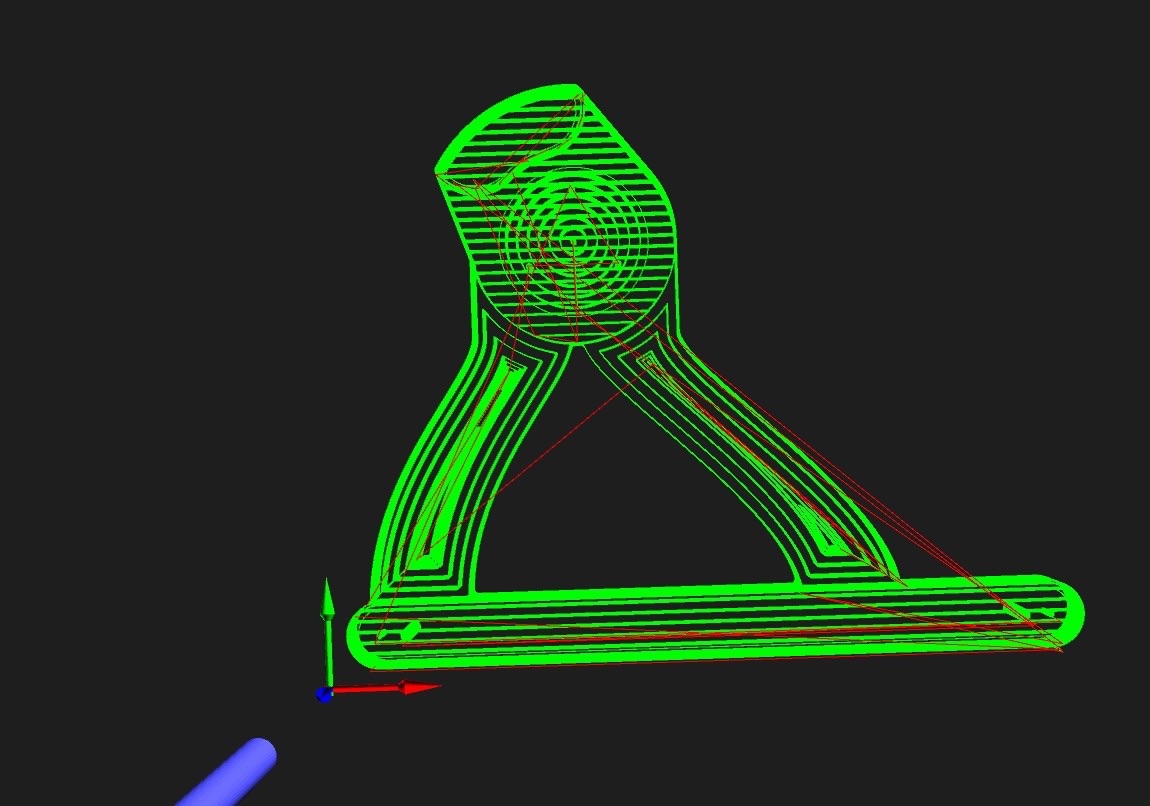

- Utilized CAM software to generate GCODE paths for the various work holding fixtures

- Set up and operated 3-axis CNC mill for fabrication of the jobs

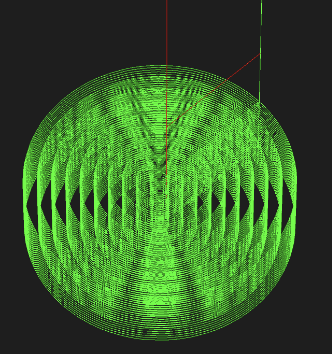

The encoder magnet rings were one of my key design and machining projects. The team needed a repeatable process to remove a 3 mm bore and, if required, enlarge the ID to 11 mm. My contributions included:

- Fixture Design: Created a CNC fixture in CAD to clamp the magnet ring without damaging the encoder magnet. Key features included a pedestal to protect the magnet, precise pocket depth for clamping, minimal offset between clamp surfaces to prevent deformation, and a transition-fit pocket for accurate alignment.

- CAM & Machining of Fixture: Generated tool paths, researched feeds/speeds, selected appropriate bits, and programmed GCODE for the mill.

- Ring Modification: Machined AISI 430 housings using a 4-flute ¼″ TiAlN-coated carbide end mill with conservative depth-of-cut parameters. Programed a circular toolpath in CAM followed by a larger diameter bit for a 70 µm finishing pass.

- Documentation: Authored detailed work instructions for technicians to reliably repeat the modification process.

Work Instructions and Workflow Process

While completing humanoid assembly, I developed comprehensive CAD-based build instructions and an assembly workflow for the entire lower body. I collaborated with process engineers and technicians to gather feedback and refine both the instructions and overall workflow for efficiency and clarity.